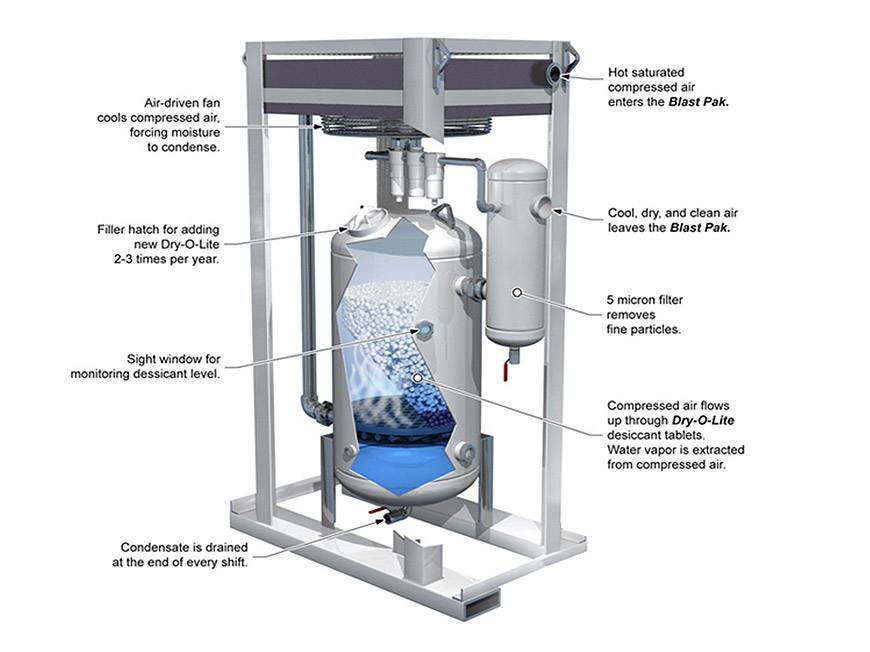

The process of activated alumina works on the simple premise of trapping the moisture to the material once the air passes through. JALON’s activated alumina products are superior to its peers, as they have larger water adsorption capacities comparing to molecular sieves at a higher relative humidity levels. They are conditioned to stay stable at or below dew point specifications, allowing for longer use and a more refined finsihed product.

A typical use for activated alumina is as a partner to molecular sieves in deep drying liquid or gasses for petrochemical products. Its larger particle size complements the finer adsorption capabilities of molecular sieves, protecting the sieves and extending the service life.