We value your privacy

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.

We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorized as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

No cookies to display.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

No cookies to display.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

No cookies to display.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

No cookies to display.

Advertisement cookies are used to provide visitors with customized advertisements based on the pages you visited previously and to analyze the effectiveness of the ad campaigns.

No cookies to display.

Aptitude Connect is a close partner of Jalon. Jalon 13X molecular sieve has shown excellent performance in many projects and been widely recognized by end users in the local market. Meanwhile, customer service and technical support provided by the Jalon team are approved by the client.

WWRC Malaysia Sdn Bhd have been purchasing zeolite product from Luoyang Jalon Micro-nano New Materials Co., Ltd for years, as moisture absorber applied in PU systems. Jalon’s JLH Series Activated Zeolite Powder has been widely adapted and used by end customers in Malaysia. These customers highly evaluated it’s quality and product performance. It is also highly recommended to customers in manufacturing products of PU system like adhesive, sealant and coating.

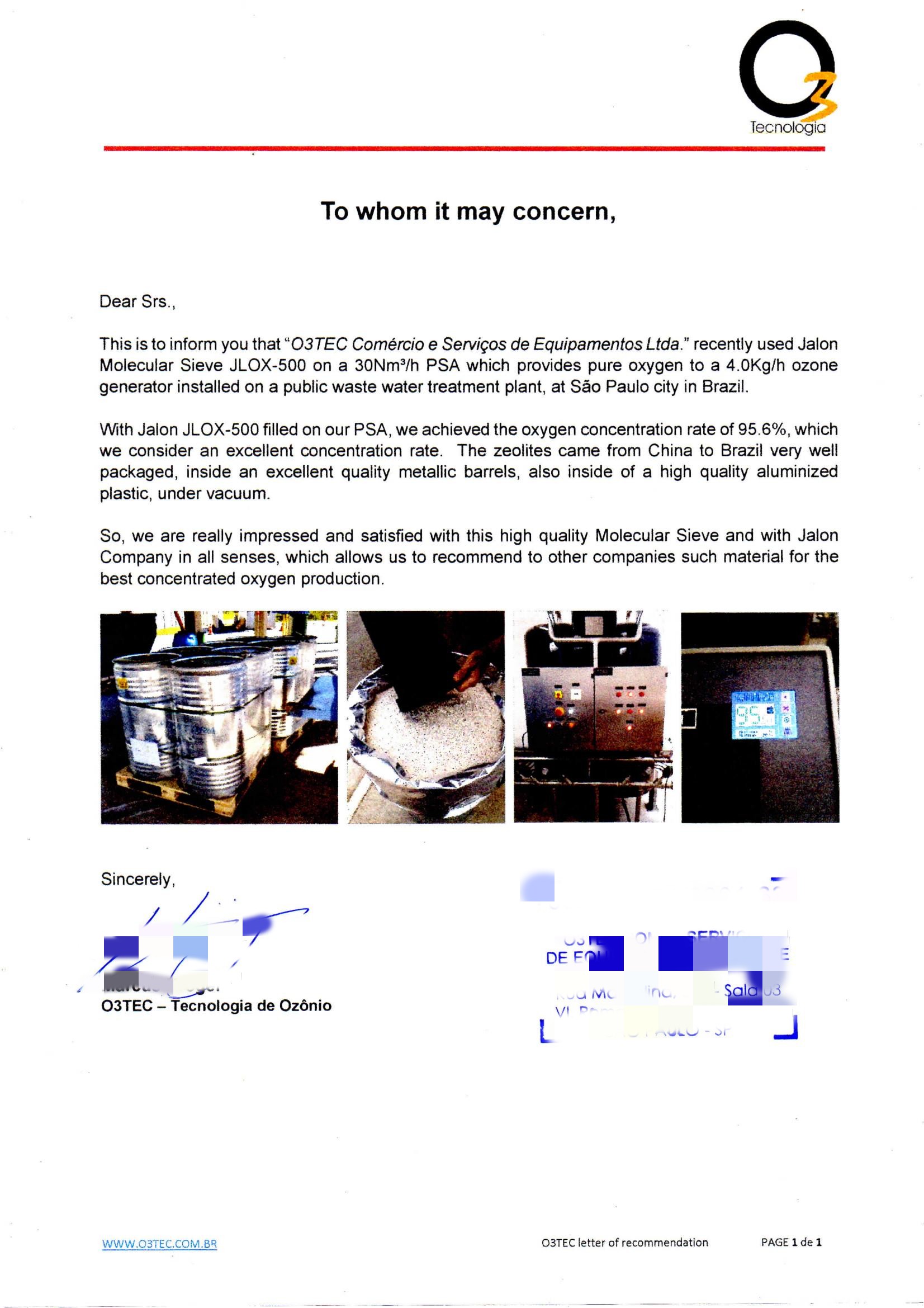

This is to inform you that “O3TEC Comércio e Serviços de Equipamentos Ltda.” recently used Jalon Molecular Sieve JLOX-500 on a 30Nm/h PSA which provides pure oxygen to a 4.0Kg/h ozone generator installed on a public waste water treatment plant, at São Paulo city in Brazil.

With Jalon JLOX-500 filled on our PSA, we achieved the oxygen concentration rate of 95.6%, which we consider an excellent concentration rate. The zeolites came from China to Brazil very well packaged, inside an excellent quality metallic barrels, also inside a high quality aluminized plastic, under vacuum.

So, we are really impressed and satisfied with this high quality Molecular Sieve and with Jalon Company in all senses, which allows us to recommend to other companies such material for the best concentrated oxygen production.

This letter is to inform you that we evaluated Molecular Sieve JLOED 3.0-5.0 MM product from Luoyang Jalon Micro-nano New Materials Co., Ltd to dry our organic solvents for production of electrolyte for Li ion battery. The resulting organic solvents that went through our process with the Molecular Sieve JLOED 3.0-5.0 MM product in our R/D and production facility located in Chico, CA, US passed our specifications showing extremely low content of moisture, below 10ppm. This Molecular Sieve product met our quality requirement, and it is highly recommended for use in the industry of Li ion battery for drying of organic solvents. We also appreciate the technical support from the company.

Nanotech Energy

Luoyang Jalon Micro-nano New Materials Co., Ltd. JLPM series molecular sieves are mainly used for cryogenic drying of general industrial gases. The purification system in the air separation unit removes H2O and CO2, as well as natural gas and other hydrocarbon desulfurization (removal of H2S and mercaptans) and CO2.

It is worth mentioning that Yuntianhua United Commerce Co., Ltd. Company 52000 Nm3/Cryogenic air separation unit project. The design and manufacture method of the air separation unit by air, adsorber adopt vertical radial flow design, processing capacity of 311352 nm3 / h, 5.13 Bar (A) adsorption pressure, loading type my company JLPM3 efficient molecular sieve 92 tons, 107 tons of activated alumina, can ensure that the CO2 content in the air mean 1000 parts per million (2000 PPM) instantaneous equipment and stable operation, export CO2 molecular sieve < 0.1 PPM.

The fifth-generation high-performance molecular sieve JLPM1 is an advanced molecular sieve used in the pre-purification unit (APPU) of air separation equipment. Compared with previous generations, the fifth-generation high-performance molecular sieve JLPM1 has significantly improved CO2 adsorption capacity; the fifth-generation high-performance molecular sieve JLPM1 will bring multiple benefits to air separation designers and operators. For the design of the new air separation plant, the application of the fifth-generation high-performance molecular sieve JLPM1 can make the air separation occupy a smaller area, thereby reducing equipment investment and operating costs. The fifth-generation high-performance molecular sieve JLPM1 can also be used for the transformation of old equipment, which can reduce energy consumption or improveair separation processing capacity.

Oxygen molecular sieve is an important material to ensure the work of VPSA oxygen production equipment. This project is another successful case of our JLOX-103 lithium-type high-efficiency oxygen molecular sieve.

The 30000Nm3/h pressure swing adsorption (VPSA) oxygen production project of Zhuhai Yueyufeng Iron and Steel Co., Ltd., designed and built by CSSC Huanggang Precious Metals Co., Ltd., was successfully started up on June 27, 2019. As of May 29, 2020, the device has been operating stably for 11 months, and all indicators are better than the design indicators. It has been highly recognized and praised by customers, and has created a cumulative effect of 150 million yuan per year for the enterprise. At the same time, the project has realized intelligent oxygen production, mobile control and remote monitoring to guide production, helping to realize the green and intelligent promotion of the industry.

The project uses 4 sets of pressure swing adsorption (VPSA) oxygen generators in parallel. The single set of device is designed to produce 7500Nm3/h of oxygen and 80% oxygen purity. It is filled with our company (Luoyang Jalon Micro Nano New Materials Co., Ltd.) JLOX-103 lithium-type high-efficiency oxygen molecular sieve is 68 tons, the actual oxygen output reaches 7650Nm3/h, and the oxygen concentration is above 82.3%. The 4 sets of equipment in this project are filled with 272 tons of our JLOX-103 oxygen molecular sieve, with a total oxygen production of more than 30000Nm3/h.

Oxygen molecular sieve is an important material to ensure the operation of VPSA oxygen production equipment. This project is another successful case of our company’s JLOX-103 lithium-type high-efficiency oxygen molecular sieve.

Luoyang Jalon Micro-nano New Materials Co., Ltd. JLOX-100 series high-efficiency oxygen generation molecular sieve is a lithium X-type aluminosilicate crystal, which is an oxygen generation molecular sieve with international advanced level. Widely used in: iron and steel, non-ferrous metallurgy, chemical industry, furnace energy-saving transformation, environmental protection, papermaking, aquaculture, medical care and other industries.

The PSA oxygen generator uses zeolite molecular sieve as the adsorbent, and uses the principle of pressure adsorption and decompression desorption to adsorb and release oxygen from the air, thereby separating oxygen. The separation effect of zeolite molecular sieve on O2 and N2 is based on the small difference in the dynamic diameter of the two gases. N2 molecules have a faster diffusion rate in the micropores of zeolite molecular sieve, and O2 molecules have a slower diffusion rate. With the continuous acceleration of the industrialization process, the market demand for PSA oxygen generators continues to increase, and this equipment plays an important role in the industrial industry.

JLOX-500 series high-efficiency oxygen generation molecular sieves are mainly used in pressure swing adsorption (PSA) oxygen generation devices. It has the advantages of high purity of oxygen production, high yield of oxygen production, fast adsorption rate and long service life. It is the best substitute for 5A (CaA) molecular sieve for oxygen production. JLOX-500 products are mainly used in PSA industrial oxygen production and medical center oxygen supply systems. The JLOX-501 product is a molecular sieve dedicated to PSA medical (household) oxygen generators and micro oxygen generators.

Many industrial manufacturers of PSA oxygen production at home and abroad buy our JLOX-500 series products.

Pressure swing adsorption oxygen production equipment (also known as PSA oxygen production equipment) uses PSA special molecular sieve to selectively adsorb impurities such as nitrogen, carbon dioxide and water in the air under normal temperature and pressure conditions to obtain higher purity oxygen (93 %±2).

Household oxygen generators use molecular sieve physical adsorption and desorption technology. The oxygen generator is filled with molecular sieves, which can absorb nitrogen in the air when pressurized, and the remaining unabsorbed oxygen is collected and becomes high-purity oxygen after purification. The molecular sieve discharges the adsorbed nitrogen back into the ambient air when it is decompressed, and can adsorb nitrogen and produce oxygen during the next pressurization. The whole process is a periodic dynamic cycle process, and the molecular sieve is not consumed.

JLOX-100 series of high-efficiency oxygen generation molecular sieve is a lithium X-type aluminosilicate crystal, which is an oxygen generation molecular sieve with international advanced level. The JLOX-101 product is a high-efficiency oxygen molecular sieve used in high-end small medical (home) oxygen generators.

JLOX-500 series high-efficiency oxygen generation molecular sieves are mainly used in pressure swing adsorption (PSA) oxygen generation devices. It has the advantages of high purity of oxygen production, high yield of oxygen production, fast adsorption rate and long service life. It is the best substitute for 5A (CaA) molecular sieve for oxygen production. The JLOX-501 product is a molecular sieve dedicated to PSA medical (household) oxygen generators and micro oxygen generators.

We have a lot of oxygen manufacturer customers to buy our JLOX-100&JLOX-500 series products, Longfian Scitech Co., Ltd, CANTA, and Kaiya Medicale,etc

In May 2014, Luoyang Jalon Micro Nano New Materials Co., Ltd. and Inner Mongolia New Energy Energy Co., Ltd. signed a cooperation agreement on the molecular sieve and dehydrating agent project.

New Energy Energy Co., Ltd. is located in Dalate Banner, Ordos City, Inner Mongolia. It covers an area of six square kilometers. It uses coal as raw material. According to the national energy industry policy, combined with its own corporate advantages, it introduces mature coal chemical technology at home and abroad, and uses the local rich coal resources, development and construction of new clean energy production bases in line with the national energy strategy. The first phase is to invest in a coal-to-methanol project with an annual output of 600,000 tons. The project process uses two sets of 45,000 Nm3/h air separation equipment, using the new high-efficiency JLOX-300A molecular sieve and dehydrating agent activity alumina. The device switching time has been extended from the original 4 hours to 6.5 hours. After strict performance assessment, the technical performance of the products provided by our company meet the requirements of the contract and technical specifications, and the parameters meet the requirements of process operation.

Our company launched the JLOX-300A series of spherical molecular sieves in 2010. After continuous technological innovation, the production process of the JLOX-300A series of spherical molecular sieves has become more mature and the product quality has been steadily improved. Mainly used in cryogenic air separation equipment with different process requirements. Because the JLOX-300A series spherical molecular sieve has excellent CO2 adsorption performance under low CO2 partial pressure conditions (for example, under the conditions of CO2 concentration of 450ppm, adsorption gas pressure of 0.7MPa.A, and adsorption temperature of 25℃, JLOX-300A’s dynamic adsorption capacity can reach 1.7 times of 13XAPG), therefore, the JLOX-300A series spherical molecular sieve, as a new generation of the high-efficiency special adsorbent for cryogenic air separation purification, has attracted market attention and gradually gained market recognition.

Shaanxi Yanchang Petroleum Yulin Coal Chemical Co., Ltd. (“Yulin Coal Chemical” for short) is a large-scale energy and chemical enterprise under the umbrella of Shaanxi Yanchang Petroleum (Group) Co., Ltd., which integrates the comprehensive conversion and utilization of coal, oil, chemical and electricity. It was completed and merged in January 2012. Put into production of 200,000 tons/year acetic acid and its supporting projects. After upgrading in 2014, the annual production capacity of methanol and acetic acid reached 250,000 tons and 300,000 tons respectively. In 2015, the company built the first domestic 150,000-ton/year syngas-to-liquid demonstration device using cobalt-based Fischer-Tropsch synthesis technology.

In the second phase, it is planned to construct equipment with an annual output of 1.5 million tons of methanol, 400,000 tons of acetic acid, 300,000 tons of vinyl acetate, 200,000 tons of acetic anhydride, and 100,000 tons of cellulose acetate.

The first stage of PSA is used to prepare CO and is filled with JL-COS adsorbent produced by our company. The total filling capacity is 104 tons, and there are 22 adsorption towers.

In the first phase, 14 adsorption towers were operated with a processing gas volume of 12,000 m3/h, and the second phase operated 22 adsorption towers with a processing gas volume of 18,000 m3/h.

In 2018, Dongxinyuan coal tar hydrogenation workshop underwent technological transformation and replaced the pressure swing adsorption hydrogen production molecular sieve. Luoyang Jalon Micro Nano New Materials Co., Ltd. JLPH5 molecular sieve won the bid. After the project was renovated and the device was started up, the process flow was completed at one time, the hydrogen production and quality were rapidly improved, and the previous chronic diseases were completely resolved. Among them, the hydrogen production rate increased by nearly 7 percentage points, the hydrogen production increased to 23,000 m³/h, and the impurity carbon monoxide content in hydrogen decreased from 30 ppm to 50 ppm to less than 1 ppm. The daily output of refined oil is also rising, breaking through the 900-ton mark on June 29. This is also the seventh successful application performance of our hydrogen production series adsorbent in 2018.

Luoyang Jalon JLPH5 is a synthetic crystalline aluminosilicate with well-developed three-dimensional pore structure and strong polarity with pore opening of 0.5nm. Molecular sieve JLPH5 is Binderless 5A specially designed for PSA hydrogen purifications. It can also used for separation of normal paraffins from branched and cyclic hydrocarbons, PSA oxygen generation.

Dongxinyuan Chemical Company has 1.2 million tons/year blue carbon, 500,000 tons/year coal tar hydrogenation, 20,000 tons/year magnesium metal, and 2×25MW cogeneration plants. Among them, the hydrogen production device adopts PSA pressure swing adsorption hydrogen production technology. Since the device was started for one year last year, the defects in the process design and main equipment have been the shackles that the production system cannot reach production. The company established a technical transformation research team in March 2018, combined with previous practical experience, focused on discussing and researching technical transformation plans around the process technology and main equipment of the hydrogen production section, and innovatively proposed a new hydrogen production process route. The core is the previous flushing method. The purification section will be transformed to implement the “two-in-one” technical transformation and annual overhaul.

Shaanxi Yanchang Petroleum (Group) Co., Ltd. Yulin Oil Refinery is located in the eastern suburbs of Jingbian County, Shaanxi Province, and was founded in 1993. In the initial stage of the plant, the scale of the plant is only 150,000 tons/year of crude oil processing capacity and 70,000 tons/year of secondary processing capacity. After more than ten years of development, the current crude oil processing capacity of the current plant is 2 million tons/year, and the secondary processing capacity is 800,000 tons/year.

Shaanxi Yanchang Petroleum (Group) Co., Ltd. Yulin Oil (Group) Co., Ltd. Yulin Oil Refinery Joint No. 4 Workshop 13000Nm3/h Refinery Gas Hydrogen Extraction Unit Due to the production, it needs to purchase 31.0 tons of molecular sieve adsorbent for catalyst production, Luoyang Jalon Micro Nano New Material Co., Ltd. JLPH5 Molecular sieve won the bid.

| Feed gas | Before reconstruction | After reconstruction |

| H₂(%) | 93-97 | ≥99.5 |

| Production(Nm³/h) | 3500 | 7500 |

Recently, Jalon received a letter of thanks titled ‘Jalon Molecular Sieve’s Outstanding Performance in Food-Grade CO2 Purification Project’ from Sichuan Meifeng Meiser Gas Products Co., Ltd. (hereinafter Meiser Sichuan Gas)

In Nov. 2019, Meiser Sichuan Gas decided to apply the Jalon self-developed molecular sieve to their food-grade CO2 purification project, and this project started on 5th Dec. 2019.

Through 2 years of operation and test, Jalon Molecular Sieve’s performance and stability both well meet project requirements, and further guarantee the facilities’ operation. Helping our client to design, test then apply our customized molecular sieves to their facilities is what Jalon has been offering and this case is only one among many successful cooperations.

Jalon R&D center was established since the company foundation in 2002. At first, the R&D center mainly supports synthetic zeolite powder and activated zeolite powder product development and quality control. In 2005, Jalon entered the molecular sieve industry and was preparing to upgrade the R&D team. Next year, “Luoyang Molecular Sieve Engineering Technology Research Center” was set by Jalon. Now the lab has been upgraded to “Molecular Sieve Adsorbent Engineering and Technology Research Center of Henan Province”. The R&D center has advanced equipment for synthetic zeolite powder and molecular sieve basic specification test, new product (including synthetic zeolite and molecular sieve) development, and evaluation. It is also open to the public for technical service. Jalon’s R&D center consists of several specialized consultants who used to be working in different fields for decades. Their experience in facility installation, operation, and equipment loading is quite helpful in customizing molecular sieve design. Only efficient communication combined with professional knowledge can smooth the cooperation and tighten our business bond.

The molecular sieve is a class of inorganic non-metallic porous crystalline materials with large specific surface area, regular pore structure, and tunable functional units, which can effectively separate and select molecules by different diameters, polarities, boiling points, and organic hydrocarbon molecules by different degree of saturation. It has the functions of ‘sieving molecules’ and ‘shape-selective catalysis’ which makes it a strategic emerging material that can realize energy saving and emission reduction, environmental governance, and ecological restoration. Its market application is increasingly diversified, and it has more possibilities and potential growth.

According to the information released by the International Molecular Sieve Association, there are 253 types of molecular sieve structures known in the world. Under the current technical conditions, only around 20 types of molecular sieve structures such as LTA type, FAU type, and MFI type can be produced on an industrial scale.

In the future, Jalon will continue having the main business focused on molecular sieve new materials. Based on the current entire industrial chain, R&D support, automatic production line, and other advantages to continue to deepen the implementation of the “Three-field strategy”, “Internationalization strategy” and “Production diverted from adsorption to catalyst strategy”. Optimizing Jalon’s product structure to achieve differentiated development. In the meantime, we will also do our best to ensure the service of diversified customer needs and support each other to achieve common development.

Recently, Jalon received a report titled ‘Performance Report of Jalon Molecular Sieve in Overseas 80,000Nm3/h Cryogenic Air Separation Project’ from a client of the cryogenic equipment industry in Hangzhou. This facility has been adjusted to reach the designed production capacity by the end of 2021. The Cryogenic air separation equipment and molecular sieve purification system are both operating well. Jalon molecular sieve perfectly meets the technical design and the requirements of the contract after evaluation.

The molecular sieve purification system is an essential part of cryogenic air separation equipment. The humidity, ethyne, CO2, and others in the air are removed or purified to guarantee the facility’s safety and stability.

The 80,000Nm3/h air separation project above is a breakthrough in the application for Jalon, meaning our capability reaches a new level.

In 2020, the JLPM series molecular sieve is applied to three 52,000 Nm3/h Cryogenic air separation projects of Baofeng Energy, two 45,000Nm3/h Cryogenic air separation projects of ChinaCoal, the new 30,000Nm3/h Cryogenic air separation project of Shandong Shiheng Special Steel Group Co., Ltd., the new 50,000Nm3/h air separation project of Shanxi Jincheng Steel Holding Group Co., Ltd., etc. Jalon’s JLPM series molecular sieves are applied to several over 50,000Nm3/h Cryogenic air separation projects of clients from Ningxia Province to replace the imported products.

A molecular sieve is a sensitive industrial consumable with a lifetime. Jalon’s business transferred from replacement market to newly built project. Technology barrier, fund, qualification and evaluation period are challenges that Jalon has to face during development. Each successful application and client’s approval are priceless treasures to us.

With the successful cases in replacement in both cryogenic air separation projects and PSA oxygen generator projects increasing, Jalon gradually stepped into the market of newly built projects at home and abroad. Jalon’s JLOX-300 series, JLPM series, and JLOX-100 series have been qualified and accepted to replace the equivalent imported products in cryogenic air separation and PSA oxygen generators. Jalon is now capable to compete with international factories with its wide product range and consistent quality.