A product’s quality and shelf life are critical, especially in the healthcare industry. Medications on store shelves or dispensed by a pharmacy do not degrade or lose effectiveness while waiting to be used.

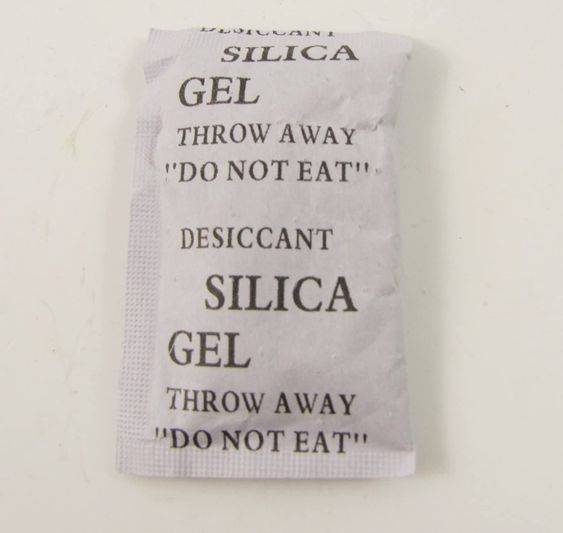

Desiccants, such as Montmorillonite Clay or Silica Gel, are compounds or agents that absorb moisture from the air to help create low-humidity environments. They are typically used in the transportation, storage, or maintenance of materials and products.

Many companies add a desiccant to pharmaceuticals, supplements, vitamins, and diagnostic products like pregnancy tests to control moisture and maintain the product’s effectiveness over time.

In this article, we will go over:

- Zeolite Molecular Sieve Vs Silica Gel

- Which one should you choose: Molecular Sieve or Silica Gel?

- Are There Any Adverse Effects Of Desiccants On Pharmaceuticals?

The Differences Between Zeolite Molecular Sieve And Silica Gel

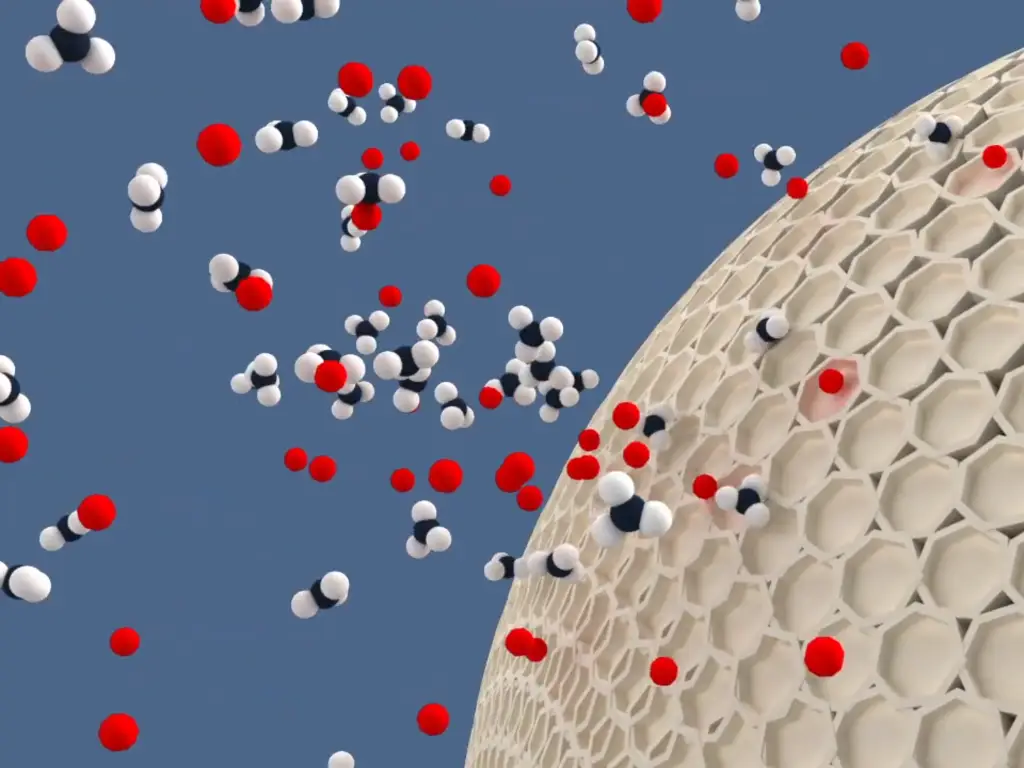

Moisture-removing desiccants like a zeolite molecular sieve and silica gel help keep products from degrading. The two desiccants, however, are very different. The following are the differences between Zeolite vs Silica gel.

Moisture Adsorption

At a few key performance criteria, the moisture absorption properties of molecular sieve and silica gel differ. While molecular sieve has an excessive adsorptive ability at low humidity, silica gel performs poorly withinside the identical conditions. At room temperature (25°C) and 40% relative humidity, both have similar moisture retention capacities.

When compared to similar amounts of silica gel, a molecular sieve has a faster rate of absorption, resulting in faster moisture removal. Free moisture penetrates the molecular sieve pores at a faster rate than silica gel. When using a molecular sieve, it interprets to quicker attainment of distinct relative humidity levels in pharmaceutical packaging.

Effect Of Temperature

Temperature changes affect the properties of both desiccants in different ways. The adsorptive capacity of silica gel decreases at high temperatures, and it may leak moisture into the packaging. Because of a uniform structure that strongly binds water even at higher temperatures, molecular sieve has excellent moisture retention properties at higher temperatures.

Which one should you choose: Molecular Sieve or Silica Gel?

What to choose? Silica Gel vs Molecular Sieve. While the differences between molecular sieve and silica gel are explained above, there are many other factors to consider when choosing a desiccant for your product. Consider the following additional factors before making a decision:

- Relative humidity

- Temperature range

- Moisture fluctuations

- Pressure changes

- Mechanical forces

- Assembly options

In products with stable storage temperatures and high relative humidity, silica gel would be an excellent desiccant. Silica gel is a popular desiccant choice in many pharmaceutical products due to its inert, non-toxic, and stable nature. Large temperature variations must be avoided at all costs, as they can affect the performance of silica gel.

Molecular sieve would perform better in products that require quick moisture protection due to its aggressive and rapid water adsorption properties. The mol sieve is more stable over a wider temperature range and has better moisture retention. When selecting the proper dosage for use in products with specific RH requirements, caution must be exercised.

Are There Any Adverse Effects Of Desiccants On Pharmaceuticals?

Both molecular sieve and silica gel are easy to include right into a product. Desiccants come in a variety of forms, from packets to canisters to adhesives and everything in between; there are options for every application.

The packaging environment’s humidity should be optimized for each product, and desiccants like zeolite molecular sieve should be used sparingly. Without optimization, the packaging environment’s relative humidity may fall out of range, causing the physical and chemical properties of the API and excipients to become unstable. This optimization will guide the selection and quantity of desiccants to avoid under-or over-desiccation of pharmaceuticals.

When less-than-optimal quantities of desiccant are used, excess humidity in the packaging headspace may not be adequately removed. As a result, a chain reaction could occur, leading to the degradation of pharmaceuticals. In the presence of free moisture above their critical relative humidity, solid forms may deliquesce. The hardness of uncoated tablets decreases as their friability increases.

Gelatinous capsules have a tendency to become sticky and stick together. Many of the negative effects of under-desiccation could be mitigated by making optimal use of silica gel and molecular sieves, among other desiccants.

Overuse of desiccants, on the other hand, results in suboptimal RH in the packaging environment. When the RH falls below 30%, hard gelatine capsules become brittle and crack. Static charges build up in the packaging environment when unregulated amounts of desiccants are present, drying out medications and potentially limiting the efficiency of the API and any excipients.

Because of their aggressive nature, molecular sieve desiccants are more susceptible to over-desiccation in ambient conditions. The effects of over-desiccation in the product could be minimized by balancing the RH of both the product and the packaging environment.

Other Desiccants In Comparison To Silica Gel

Below are other types of desiccants:

1. Activated Alumina

It has a lower surface-area-to-weight ratio than silica gel and shows more variation in the amount adsorbed in response to changes in relative humidity. Activated alumina is commonly utilized in heatless regenerative dehumidifying devices because of its adsorption properties.

2. SK-400 Silica-Alumina

It is primarily used for heated dehumidifying equipment because it has a higher surface-area-to-weight ratio as well as greater heat and water resistance than activated alumina. When exposed to water mist, silica-alumina particles do not fracture and can be used alone.

3. SK-600 Silica Gel

It has a higher surface-area-to-weight ratio than any other type of desiccant and absorbs more moisture than any other desiccant. When exposed to mist, silica gel fractures, and its adsorption performance deteriorates when regenerated at high temperatures.

4. Synthetic Zeolite

Synthetic zeolite, unlike active alumina and silica gel, performs better in high temperatures and low relative humidity environments. A synthetic zeolite sieve is used to dry special gases and as a molecular sieve to separate certain types of molecules from mixed gases.

Conclusion

We have given you all the key differences of Silica Gel vs. Zeolite Molecular Sieve in this blog. We also gave you the differences between silica gel and other desiccants like zeolite molecular sieves.

If you want to purchase a desiccant in China, Jalon has got you covered. JALON is proud to be China’s first listed molecular sieve Adsorbents manufacturer, providing first-rate products and services for a variety of applications in a variety of industries, particularly these complex cases that our competitors find extremely difficult.